Understanding the Core Aspects of Caisson Drilling

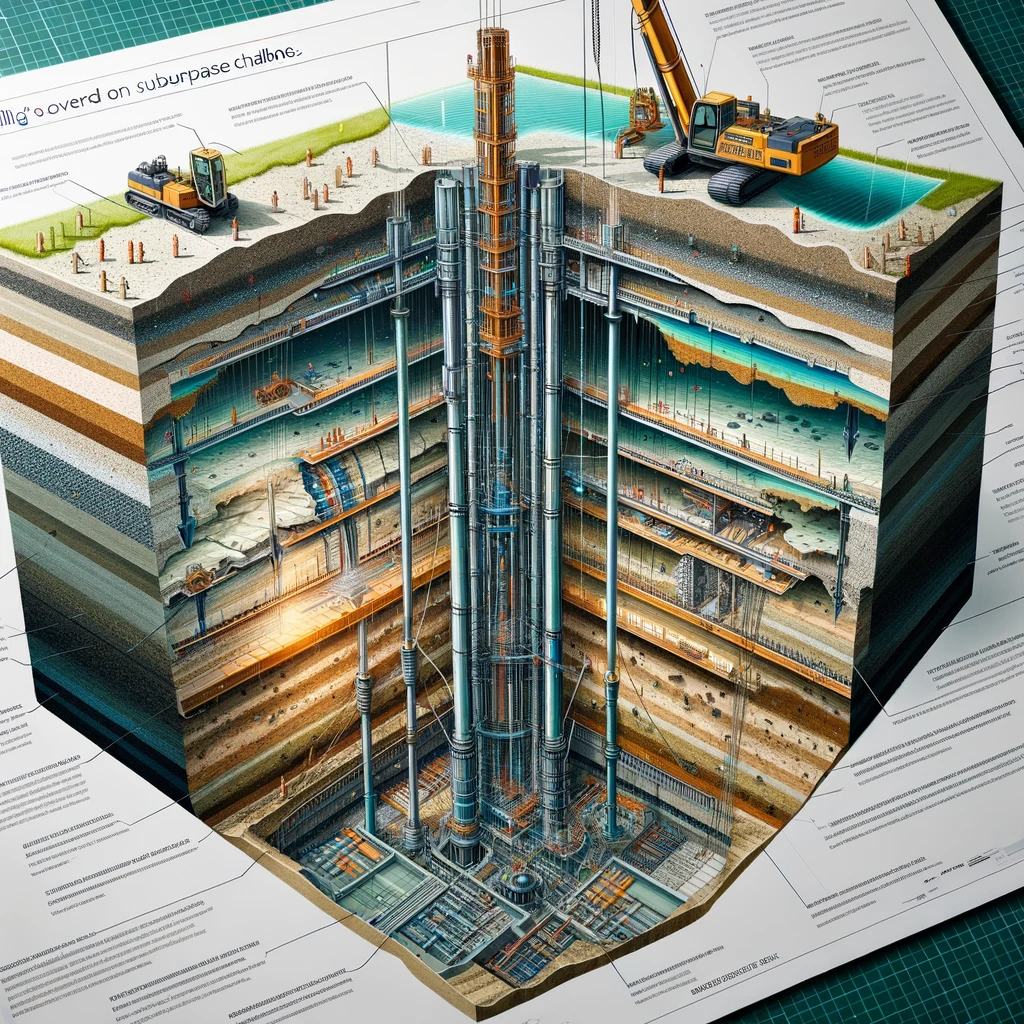

Caisson drilling plays a crucial role in overcoming challenges in subsurface construction. It is a technique used to create sturdy foundations for various structures such as skyscrapers, dams, bridges, and platforms. Caissons are large, watertight structures made of concrete or steel that are drilled into the ground to provide resistance and support against loads. The process of caisson drilling involves site investigation, drilling equipment, rock conditions, quality control, and concrete placement. It is essential to carefully design and follow instructions to ensure the integrity of the caisson shaft. However, there are inherent risks and hazards involved in caisson drilling, including groundwater levels, depth and size of the shaft, obstructions such as utilities and boulders, and deviation from the planned excavation. To overcome these challenges, proper engineering and construction techniques, such as the use of grout, drill bits, casing, and strict adherence to safety protocols, are necessary. Overall, caisson drilling is a complex process that requires expertise and careful consideration to successfully overcome the construction difficulties and achieve the desired project outcome.

Defining Caisson Drilling and Its Significance in Construction

Caisson drilling plays a crucial role in overcoming challenges in subsurface construction. This specialized technique involves a step-by-step process that requires careful risk assessment and contingency planning. From the inspection of the soil heterogeneity to the design alignment and orientation, every aspect of the caisson drilling process is meticulously executed to ensure optimal performance. The use of slurry, caisson heads, laser beams, bobs, and verticality control systems helps maintain the precise position of the drilling tools. Despite the drilling difficulties that may arise from soil conditions or human error, the supervision and stability measures implemented during caisson drilling contribute to the integrity of the foundation design. By effectively mitigating the risk of collapse, groundwater pressure, and vibrations, caisson drilling allows for the successful completion of subsurface construction activities and projects, ensuring the quality and safety of the retaining wall project.

Caisson construction problems can present various construction difficulties. To overcome these challenges, caisson drilling is employed. With the use of specialized drilling equipment and techniques, caisson drilling addresses the unique obstacles encountered in subsurface construction projects. The process involves the careful coordination of suppliers, subcontractors, and manufacturers to ensure the availability and quality of the needed materials and equipment. The proper installation and maintenance of caissons are critical to their performance and bond with the surrounding soil. Attention to details such as segregation, bleeding, and cold joints are also essential to prevent potential structural issues. Articles on pile settlement and strip foundations provide valuable insights into the effects caisson drilling can have on the overall concrete foundation design. By overcoming these challenges, caisson drilling enables the successful completion of construction projects, ensuring the stability and structural integrity of the foundations.

Variety of Applications for Caisson Drilling in the Construction Industry

Caisson drilling plays a crucial role in overcoming challenges in subsurface construction, and its applications in the construction industry are diverse. One application includes the construction of cofferdams, which are temporary structures used to create a barrier between the construction site and water bodies. Caisson drilling is essential in this process as it allows for the drilling of deep foundation shafts and the installation of wells for soil testing. Additionally, caisson drilling is vital in the planning and execution of projects, as it helps address issues related to different soil types and conditions. It enables rock cutting and jet grouting performance, factors that contribute to the durability and stability of the foundation. Another application of caisson drilling is the use of suction anchors, which are commonly employed in offshore construction. This technique helps to secure and stabilize structures such as hospitals, buildings, and ventilation buildings in challenging locations like midtown Manhattan, where the river and other constraints pose significant obstacles to building foundations. By drilling caissons into the rock or soil, the construction difficulties can be overcome, allowing for the successful completion of the project.

The Technical Process Behind Caisson Drilling

Caisson drilling is a crucial technique in overcoming challenges in subsurface construction. In a recent construction project, the use of caissons proved essential in building an underground parking system on a crowded campus. With limited space and numerous constraints, the construction team faced significant difficulties. However, by employing caisson drilling, they were able to overcome these challenges. For instance, in one case, two caissons were drilled to create an easement for commuter train lines. The project also involved drilling caissons for the construction of a steel shoreline and multiple layers of caissons for the hospital building. The caissons, reinforced with steel bars, provided a solid foundation for various structures, including operating rooms and inpatient rooms. With the help of caisson drilling, many barriers were overcome, and the project was completed successfully. The collaboration between Ennead Architects and NBBJ resulted in a tower with research facilities, passageways, and utilities integrated into the caisson structure, including tunnel tubes connecting the hospital to other buildings on Hospital Row. Through careful planning and execution, the construction team was able to navigate the challenges and ensure a safe and efficient construction process. Additionally, a comprehensive monitoring program was in place to track the stability of the caissons, ensuring that they were securely embedded in the bedrock below the flood risk zone. This monitoring program included regular checks and analysis of rock core results, ensuring the quality and stability of the caissons. The caisson reclamation process involved removing the upper layers of soil and rock, creating a flat platform for construction. The caisson drilling technique thus proved invaluable in overcoming challenges in subsurface construction, enabling the successful completion of complex projects.

Examination of the Caisson Drilling Technique

Caisson drilling is a technique used to overcome challenges in subsurface construction. It involves the creation of a foundation trench structure that extends below the ground surface. The construction process typically begins with the installation of timber or steel sheeting to stabilize the shoreline bulkhead. Class 1 foam is then injected into the caisson to provide buoyancy during drilling operations. The caisson is drilled using a combination of threadbar and column loads to penetrate the underlying soils. This method is particularly effective in areas with soft soils such as clay, silt, and sand. By drilling caissons, construction teams can overcome the majority of ground floor, tunnel zone, and property challenges that may arise in subsurface construction, such as handling rubble, dense sand, and Manhattan schist rock.

Caisson drilling has a significant impact on the infrastructure and building structure. The construction of caissons allows for the creation of sturdy foundations, especially in areas with high water levels or docks. Different types of caissons can be used depending on the project requirements, with diameters ranging from small to large. For tunnel construction, caissons with rock sockets are employed to handle the pressure and provide stability. The length of the socket depends on the dimensions of the tunnel, ensuring that the caissons are securely anchored. Concerns such as entrances, parking entrances, and wave loads are all addressed through the design of flood barriers and swing barriers, which are integrated into the caissons. The capacity and stability of the caissons are carefully analyzed, considering factors such as tunnel spring line, caisson tip elevations, and design flood elevation. By overcoming these challenges, caisson drilling plays a crucial role in subsurface construction projects.

Machinery and Equipment Involved in Caisson Drilling

Caisson drilling plays a crucial role in overcoming challenges in subsurface construction. The machinery and equipment involved in this process are specifically designed to tackle these difficulties effectively. For instance, when constructing buildings with ground floor elevator entrances, the use of rock quality, threadbar lengths, and rock socket lengths are carefully considered to ensure the stability and caisson capacity. In cases where building transfers or schedule constraints are present, the concrete spoils and tolerance controls become essential for maintaining the integrity of the structure. Additionally, the tunnel proximity, cantilever foundation plate girders, and CSO (Combined Sewer Overflow) caisson elements require a thorough study to determine the optimal span transfers, waterproofing system, and bathtub system. Overcoming these challenges with the proper machinery and equipment ensures a strong foundation and benefits like flood protection and shoreline bulkheads.

When it comes to the machinery and equipment involved in caisson drilling, the foundation schedule and times are critical factors to consider. Reinforcement couplers, approach to threadbar reinforcement, and opening for MEP (Mechanical, Electrical, Plumbing) zones are carefully devised. The slab and superstructure rely on the many decisions made during the drilling process. The rotary drilling methods, reverse circulation, and hammer are chosen based on the nature of the project and the desired verticality and deviation control. In addition to the drilling techniques, the choice of machinery plays a significant role in overcoming construction difficulties. This is particularly important in cities where space is limited, and projects like sewer outfall pairs need careful planning. With the right combination of machinery and equipment, caisson drilling effectively addresses the challenges of subsurface construction, ensuring a strong foundation for any project.

Overcoming Subsurface Construction Challenges with Caisson Drilling

Caisson drilling plays a crucial role in overcoming challenges in subsurface construction. Geotechnical engineers often encounter various difficulties when working on underground projects, such as load shedding and spacing requirements. To address these issues, caissons – large cylindrical structures – are drilled into the ground. These caissons act as foundations, providing support for structures like basements and loading docks. The effects of caisson drilling are far-reaching, as it enables the construction of structures of different sizes and shapes. By utilizing field welding extensions and the flexibility of different sizes of tremie pipe, the installation of caissons becomes more efficient. This flood protection technology is commonly used for the construction of flood walls, concrete bathtubs, and other barrier types. When considering site constraints and the need to maintain the functionality and aesthetic of a building’s facade elements, caissons offer a reliable system for withstanding flood loads and flood waters. The design considerations, such as the inclusion of drop panels and the building perimeter, ensure proper protection against flooding. Additionally, caisson drilling incorporates different materials, such as stone, from various vendors to enhance the project’s resilience. Factors like the loading dock ramp and submarine doors provide multiple points of egress during emergency situations. The use of fiberglass produces lighter yet stronger components that can counteract uplift forces from the soil. Not only does caisson drilling address challenges in subsurface construction, but it also offers solutions for ground-level construction, such as creating openings for diameter casings without affecting flood protection measures. To overcome these difficulties, caissons are drilled into the ground, and the force couple between the soil and anchors ensures stability. Caisson drilling proves to be a valuable technique for overcoming challenges and providing robust solutions in subsurface construction projects.

Role of Caisson Drilling in Tackling Subsurface Obstacles

Caisson drilling plays a crucial role in tackling subsurface obstacles in construction projects. With its minimum design, advanced tie-down anchors, and state-of-the-art machinery, caisson drilling is able to overcome various challenges that arise in subsurface construction. For example, when constructing a new building in a community, the team may encounter difficulties in excavating below street level and sidewalk pavement. By using caissons, a series of vertical metal strips that create a stable foundation, the construction team can overcome these obstacles and ensure proper clearance for the building’s foundation. The soil mass is carefully analyzed, and the caissons are designed to withstand the pressure and ground water elevation, taking into consideration flood elevations and loading docks. This risk of flood uplift support is addressed through the revision of the project’s proximity to FEMA flood maps and the need for MEP (Mechanical, Electrical, Plumbing) systems to be elevated using mini-caissons. This rethinking of the construction methods and practices ensures that the project is resilient in the face of sandy, flood-prone areas and aligns with the standards set by emergency management agencies. By incorporating caisson drilling into the construction process, challenges related to flooding, ground stability, and future sea level rise can be overcome, allowing for increased safety and functionality of the building.

Case Studies: How Caisson Drilling Addressed Subsurface Construction Issue

Caisson drilling has proven to be an effective solution for overcoming challenges in subsurface construction. Through various case studies, it has been demonstrated that caisson drilling techniques have successfully addressed construction difficulties. In projects such as the Crossrail project, engineers have utilized advancements in caisson drilling to overcome caisson construction problems and ensure the smooth execution of the construction process. This evolution in construction methods has been a significant factor in the successful completion of engineering projects, including the construction of tunnels and shafts. By employing caisson drilling, project managers and construction teams have been able to overcome challenges and achieve sustainable construction methods, conserving resources and minimizing energy consumption.

In the field of caisson drilling, various topics have been the focus of study and analysis. Microtunneling, for instance, has emerged as an important technique, addressing the need for excavation and creating transportation systems with minimal impact. The importance of ventilation systems, water management systems, and heating systems in caisson construction cannot be understated. Additionally, the impacts of tunnel boring machines, waste management, and engineering practices have all been areas of research and development. By delving into these topics, engineers and construction experts have been able to improve the efficiency and sustainability of caisson drilling projects, overcoming challenges and ensuring successful construction in subsurface areas.

Safety Measures and Precautions in Caisson Drilling

When it comes to caisson drilling, safety measures and precautions play a vital role in ensuring the well-being of workers and the preservation of the environment. The construction process involves overcoming challenges in subsurface construction, where the design and ground conditions may present various obstacles. By implementing necessary safety protocols, such as proper ventilation and lighting, and developing waste management plans, caisson drilling projects can effectively mitigate potential risks and hazards. Case studies, such as the Gotthard Base Tunnel in Switzerland and the Crossrail project in London, demonstrate the urgency and advantages of prioritizing safety in caisson drilling. This not only ensures the functionality and longevity of the drilled caissons but also reduces the project’s carbon footprint by minimizing greenhouse gas emissions and waste generation. Ultimately, by considering safety as a fundamental aspect from the planning stage to the completion of caisson drilling projects, the industry can achieve a balance between construction efficiency and the well-being of both workers and the public.

Necessary Safety Protocols in Caisson Drilling Operations

Caisson drilling in subsurface construction presents various challenges that require necessary safety protocols to ensure the well-being of workers and the successful completion of projects. The significance of these protocols cannot be overstated, as caisson drilling involves precise engineering techniques and the presence of heavy machinery. Safety measures such as the use of monitoring systems, strict adherence to construction guidelines, and the implementation of recycling strategies to reduce carbon emissions and waste are crucial. By addressing potential risks and hazards, caisson drilling operations can overcome construction difficulties and create sustainable infrastructure projects in cities.

When it comes to caisson drilling in subsurface construction, safety is a paramount aspect that cannot be overlooked. The precision and accuracy required in caisson drilling techniques demand advanced safety measures to ensure the well-being of workers and the reliability of the infrastructure. From the drilling of caissons for tunnel excavation to the construction of shafts and conduits, safety protocols are essential. These protocols include monitoring soil conditions, implementing effective ground stabilization techniques, and using tunnel alignment and tunneling machines with efficient features. By prioritizing safety, the construction industry can overcome challenges in subsurface construction while also creating a transportation system that enhances speed, performance, and sustainability.

Dealing with Potential Risks and Hazards in Caisson Drilling

Caisson drilling presents its fair share of potential risks and hazards. It is crucial for contractors to take proactive measures to address these challenges and ensure a safe working environment. One of the primary risks in caisson drilling is the stability of the soil or ground surrounding the drilled caissons. As the drilling process progresses, there is a possibility of ground settlement and surface disturbance, which can impact nearby transportation networks and surface infrastructure. To control and mitigate these risks, innovative control systems and technologies such as laser alignment and tunnel injection technologies can be employed. Additionally, collaboration between contractors, engineers, and project stakeholders is essential in identifying and addressing potential risks in a timely manner, improving project resilience and accessibility.

Caisson drilling in subsurface construction comes with its own set of challenges. Contractors must overcome these difficulties to ensure successful project completion. One of the key challenges is the alignment of caissons, especially when dealing with large-diameter caissons. The precision required in drilling shafts and maintaining structural integrity can be demanding. Furthermore, the presence of utility pipelines and other underground infrastructure poses a risk of disruption and increasing construction costs. To overcome these challenges, contractors need to employ advanced drilling machinery and equipment, such as tunnel boring machines (TBMs) and auger systems, to ensure accurate and efficient drilling. By leveraging innovation and implementing effective risk management strategies, caisson drilling can be optimized to benefit infrastructure development while minimizing the potential risks and hazards associated with construction in subsurface environments.

Evaluating the Environmental Impact of Caisson Drilling

Evaluating the environmental impact of caisson drilling is crucial in understanding the overall sustainability of this construction technique. Caisson drilling, which is often used to overcome challenges in subsurface construction, requires careful monitoring and assessment of its effects on the environment. One important aspect to consider is the maintenance requirements of drilled caissons. Ensuring the straightness and ability of the caissons is essential to avoid settlement and potential collapse. Furthermore, investigations into tunnel injection technologies and maintenance of the drilled caissons should also be conducted to minimize any negative impact on the environment. From a transportation capacity perspective, caisson drilling has proven beneficial in tackling urbanization challenges by providing access to water bodies and enabling the installation of pipelines and cables without disrupting surface activities. The excavation accuracy and efficiency of caisson drilling allows for inspection and inspection of the surrounding environment, making it a viable option for construction endeavors worldwide. For example, in Zurich, the caisson drilling method was used in the construction of the Elizabeth Line railway line, which increased job opportunities and stimulated the local economy. Stakeholder engagement and the use of advanced technologies, such as laser beams, also contribute to the smoothness and accuracy of caisson drilling, reducing errors and tunnel deviation. Overall, evaluating the environmental impact of caisson drilling is vital in ensuring its sustainability and addressing any potential challenges that may arise from this construction technique in subsurface environments.

Detailed Analysis of Caisson Drilling’s Effect on the Environment

Caisson drilling has revolutionized the construction industry by overcoming challenges in subsurface construction. This breakthrough technique has successfully addressed construction difficulties and caisson construction problems by utilizing drilled caissons. With the help of caisson drilling, projects that involve building tunnels, roads, viaducts, and basements can now be executed with greater construction efficiency and coordination. The drilling method involves creating holes in the ground and using grouting materials to ensure waterproofing and stability. Caisson drilling has been employed in various civilizations throughout history, from military applications to the creation of art and subways. Its importance in improving construction speed and overcoming subsurface challenges cannot be overstated.

Caisson drilling has played a vital role in reducing the disturbance caused by traditional excavation processes in subsurface construction. By using drilled caissons, construction activities can be directed in specific volumes and directions, minimizing disruptions to transit connectivity and reducing congestion on roads. The execution and coordination of construction projects have been greatly improved through the use of caissons. Additionally, the caisson method offers significant advantages over mining techniques, as it does not require extensive excavation or the use of explosives. The invention of caisson drilling has not only led to breakthroughs in construction, but it has also helped in preserving the environment and ensuring the structural integrity of infrastructures. From the construction of tunnels through the Swiss Alps to the creation of transport tunnels, caisson drilling has proven to be a versatile and efficient solution for overcoming challenges in subsurface construction.

Conclusion

Caisson drilling has emerged as a crucial technique in the construction industry, enabling the successful completion of projects by overcoming various challenges in subsurface construction. The origins of caisson drilling can be traced back to China, where pioneers developed tools and methods that are still used today. The durability and strength of caissons make them ideal for constructing underground structures such as subway systems, residences, and even artificial intelligence (AI) and robotics research spaces. In cities like Milan, progress in humanity’s exploration and expansion of underground spaces is being made possible through caisson drilling. The use of AI and robotics in caisson drilling has increased safety measures and automation, reducing human intervention and ensuring the endurance and traction necessary to complete complex drilling tasks. Despite the capital investment and site conditions that may pose boundaries, caisson drilling continues to prove its worth in addressing construction difficulties. By implementing laser guidance and conducting thorough research on rock conditions, caisson drilling can overcome challenges and provide a reliable solution for subsurface construction projects.

FAQS

What is caisson drilling?

Caisson drilling is a technique used in construction to create deep, watertight foundations for structures such as bridges, piers, and buildings. It involves drilling large diameter holes into the ground and filling them with concrete or other materials to provide stability and support.

Why is caisson drilling significant in construction?

Caisson drilling is significant in construction because it allows for the construction of structures in areas with challenging soil conditions or high water tables. It provides a reliable foundation that can withstand the pressures of the surrounding environment.

What are some common applications of caisson drilling in the construction industry?

Caisson drilling is commonly used in the construction industry for various applications including bridge foundations, high-rise building foundations, retaining walls, flood control structures, and offshore oil and gas platforms.

How does the caisson drilling process work?

The caisson drilling process begins with the drilling of a hole into the ground using specialized drilling equipment. Once the desired depth is reached, reinforcing steel is placed in the hole, and concrete is poured to fill the void. The concrete is allowed to cure, creating a solid foundation for the structure.

What machinery and equipment are involved in caisson drilling?

Caisson drilling requires specialized machinery and equipment such as drilling rigs, augers, casings, and concrete pumps. These tools are used to drill, support the hole, and deliver the concrete into the drilled shaft.

How does caisson drilling overcome challenges in subsurface construction?

Caisson drilling overcomes challenges in subsurface construction by providing a stable foundation in areas with difficult soil conditions or groundwater problems. It allows for the construction of structures in locations that would otherwise be unsuitable or risky.

What role does caisson drilling play in tackling subsurface obstacles?

Caisson drilling plays a crucial role in tackling subsurface obstacles by creating a strong foundation that can support heavy structures and withstand the pressures of the surrounding environment. It helps overcome issues such as soft or unstable soil, high water tables, and seismic activity.

Can you provide any case studies where caisson drilling addressed subsurface construction issues?

Yes, several case studies demonstrate how caisson drilling addressed subsurface construction issues. For example, the construction of the Brooklyn Bridge in New York City utilized caisson drilling to overcome the challenge of building foundations in underwater conditions. The use of caissons allowed for the successful completion of the landmark bridge.

What safety measures and precautions are involved in caisson drilling?

Caisson drilling involves several safety measures and precautions to protect workers and ensure the integrity of the construction process. These may include proper training, the use of personal protective equipment, regular equipment inspections, and adherence to safety protocols specific to caisson drilling operations.

What potential risks and hazards are associated with caisson drilling?

Caisson drilling presents potential risks and hazards such as cave-ins, equipment malfunctions, exposure to hazardous materials, and accidents during concrete pouring. It is important for workers to follow safety protocols and take necessary precautions to mitigate these risks.

What is the environmental impact of caisson drilling?

The environmental impact of caisson drilling depends on various factors such as the location, the depth of drilling, and the surrounding ecosystem. It may cause temporary disturbances to soil and water quality, but proper mitigation measures can minimize these impacts.

How can the environmental impact of caisson drilling be evaluated?

The environmental impact of caisson drilling can be evaluated through comprehensive environmental assessments that consider factors such as water quality, soil erosion, disturbance to wildlife habitats, and the potential release of pollutants. These assessments help ensure appropriate mitigation measures are taken.

In conclusion, what are the key takeaways regarding caisson drilling in subsurface construction?

Caisson drilling is a vital technique in subsurface construction, offering a reliable solution to overcome challenging soil conditions and water-related issues. It plays a significant role in providing stable foundations for various structures, contributing to the safe and successful completion of construction projects.